Laboratory of Surface Technologies and Degradation of Materials (Branch Office in Pilsen)

|

Department: Department of Impact and Waves in Solids Head: doc. Ing. Petr Hora, CSc. |

|

At the Laboratory of Surface Technologies and Degradation of Materials, we focus on the study of complex study of degradation of materials, heat treatment of materials and surface treatment by PVD and chemical - heat treatment methods. For metal materials, we focus on mechanical, corrosion and chemical degradation and degradation caused by temperature load strain over a wide range of temperature exposure with approximate approach of operating conditions in laboratory testing. For polymeric and composite materials, we focus on the degradation processes of temperature ageing, ageing due to exposure humidity, and radiation ageing by exposure to sunlight, both when applied in a complex form in the sun chamber and when applied separately in temperature chambers and liquid baths. The evaluation of degradation processes is monitored from initiation phases, through the development of degradation and up to final stages using sensitive analytical methods of evaluation of mechanical properties and behaviour in macro, micro and nano areas, using light microscopy and scanning electron microscopy and chemical and structure analyses. The evaluation of degradation processes is closely connected to the development of technological processes of surface treatment and heat and chemical heat treatment of materials to improve the resistance of materials against different types of degradation processes. A complex analytical evaluation of materials systems is in close connection to optimise technological processes of surface treatment by PVD methods and heat and chemical - heat treatment of materials. |

Researchers:

doc. Ing. Petr Hora, CSc.

Ing. Andrea Pechová

RNDr. Ivo Štěpánek

Bc. Lucie Štěpánová

Ing. Tereza Vaňková, Ph.D.

Secretariat:

Bc. Pavlína Strejcová, Dis.

Technical stuff:

Andrea Plecitá

Research and development focusses on:

- development and implementation of advanced technological processes in the field of surface treatment by different technological processes of PVD and PA CVD, chemical-heat treatment and heat treatment including ageing of material systems

- testing the resistance and predictive behaviour of material systems in corrosion-induced degradation processes, thermal influences, mechanical macro, micro and nano stresses and ageing processes of composite and polymer materials

- evaluation of initiation and development stages of degradation of material systems and complex properties and behaviours in surface layers of material systems as well as bulk materials of different structures

- development of methodological procedures for evaluating the results of technological processes, properties and behaviour of material systems with chemical-heat treatment, surface treatment and modifications and material systems from degradation and ageing processes

- development of methodological procedures for setting degradation and ageing processes

- computer processing of data from technological and degradation processes, computational methods and model approximations of technological processes and diagnostics

TH02010026

Development of new technologies for the manufacture of advanced tools and components.

The aim of the project is the research and development in the field of special tools with significant improved features (abrasion resistance, durability) and their manufacturing technologies friendly to the environment. The partial aim of the project is to develop a technology which would allow to manufacture these special tools also for piece / small scale production, i.e. with low production costs while maintaining their peak performance. This aim is in the context of available solutions significantly innovative and provides high added value of the project.

Research team

Ivo Štěpánek, Lucie Štěpánová, Andrea Pechová

CZ.01.1.02/0.0/0.0/15_019/0004451

Thin coats deposition - advanced tools and innovative technologies

Research and development of suitable methods of thin layer deposition and heat treatment of special tools for subsequent surface treatments. Development of technology enabling the production of newly developed special tools while maintaining low production costs and achieving greater greenness of operations.

Research team

Ivo Štěpánek, Lucie Štěpánová, Andrea Pechová

CZ.01.1.02/0.0/0.0/19_262/0020161

Optimalization of selected surface treatment of heat-resisting steel for specific operational conditions

The project solve the optimization of the selection of heat-resisting material in the connection to surface finishes to increase resistance in specific operating conditions given by the simultaneous action of corrosion, mechanical stress, erosion and/ or impact of accelerated particles. The problem of increased resistance of the base material to corrosion and resistance to mechanical fracture and erosion by surface treatment with at least equal corrosion resistance. Optimization of surface finishes and feedback analytical methods.

Research team

Ivo Štěpánek, Lucie Štěpánová, Andrea Pechová

CZ.01.01.01/08/22_001/0000232

Feasibility study of ecological change of heat treatment by advanced technologies in correlation of qualitative changes of properties and ecological load

The focus is on a feasibility study of ecological change in heat treatment with advanced heat treatment and surface treatment technologies in correlation of qualitative changes in properties, ecological stress and economics. Considering the reflection of eco-stress reduction, the selection of heat treatment methods will be implemented from the point of view of both technologies and process mediums and to achieve a qualitative effect of combining with surface treatment technologies in correlation to material quality and economics of operation.

Research team

Ivo Štěpánek, Lucie Štěpánová, Andrea Pechová

CZ.01.01.01/01/22_002/0000357

Optimization of the chemical heat treatment of special stainless steel materials with a controlled structure from the point of view of the technological operating parameters of the surface treatment and base material systems

The project solve the chemical heat treatment of special stainless steels with difficult processing from the point of view of achieving greater depths of surface modification and the necessary increase of surface hardness with the maintenance of sufficient toughness. The project solve the question of both the technological parameters of the production of selected special sealing rings and the resistance of these products under operating load conditions. In addition to technological parameters, the effect of structure properties on surface finishes will be monitored.

Research team

Ivo Štěpánek, Lucie Štěpánová, Andrea Pechová, Miloslav Mach

CZ.01.01.01/01/22_002/0000358

Optimizing the production of special components from the point of view of forming technology and increasing resistance by surface treatments to the operating conditions of thermal and chemical loads

The project solution is aimed at optimizing the technology of production of special mouldings into operationally demanding thermal chemical load conditions, from a comprehensive perspective of optimization of forming technology parameters in close relation to material characteristics of mouldings with ensuring dimensional accuracy and quality without defects and optimization of material system properties in relation to required operational temperature and corrosion resistance with ensuring limit mechanical resistance and its stability.

Research team

Ivo Štěpánek, Lucie Štěpánová, Andrea Pechová, Tereza Vaňková

Equipment for technological processes HC490

Technological processes

- low-voltage reactive arc evaporation in vacuum

according to the selection of material and structure properties of the cathode

surface treatments mainly Ti-based, Cr-based and Zr based nitrides

- binary nitrides TiN, CrN, ZrN but also HfN, TaN, WN, VN, CoN, MoN

- ternary nitrides mainly based on TiAlN, TiSiN, CrAlN....

- quaternary nitrides mainly based on TiAlSiN, CrAlSiN ...

- quinary nitrides e.g. TiAlNiSiN, CrAlNiSiN

actual cathodes for the creation of the above mentioned surface treatments

- Ti, Cr, Zr, Co, Mo, W, Ta, Hf, V

- TiAl, CrAl, TiSi, TiAlSi, TiNb, TiCu, TiNi, TiNiAlSi

- CrAlSi, CrNi, CrNiAlSi

- magnetron reactive sputtering in vacuum

Current targets:

Ti, Cr, Zr, Co, TiAl, CrAl, TiAlSi, CrAlSi, Al, Cu

- chemical heat treatment of surfaces

- plasma chemical reactions in gas and thin film deposition

- Ion implantation into the surface of materials

Optimization of technological processes

Evaluation of the effects of selected technological parameters, e.g.

- temperature

- working pressure

- partial pressures of inert and reactive gases

- Bias on deposited parts

- current at cathodes

- a controlled electromagnetic field or permanent magnetic field

- process duration in relation to the other process parameters

- power load of targets

- and a many other factors

Application direction

- increase in surface hardness

- improved friction resistence

- improved heat resistance

- improved corrosion resistance

- improved chemical resistance

- increased resistance to abrasion and erosion

- increased resistance to local fatigue

- achieving biocompatibility, bioactivity

Equipment for heat treatment

Different types of furnaces

- Annealing furnace

- Annealing and hardening furnace

- Circular furnace

- Tube furnace

- Muffle furnace

Optimization of heat treatment to achieve:

- different structure properties

- important parameter for surface treatment processes

- Hardening of selected materials (various hardening environments)

- Annealing of selected materials

- Tempering of selected materials (different tempering environments)

- Short and long term thermal resistance tests

- Load at selected temperatures and temperatures varying in different steps

Chemical heat treatment in powder environments:

- Nitriding

- Cementation

- Carbonitriding

- Nitrocementation

- Boriding

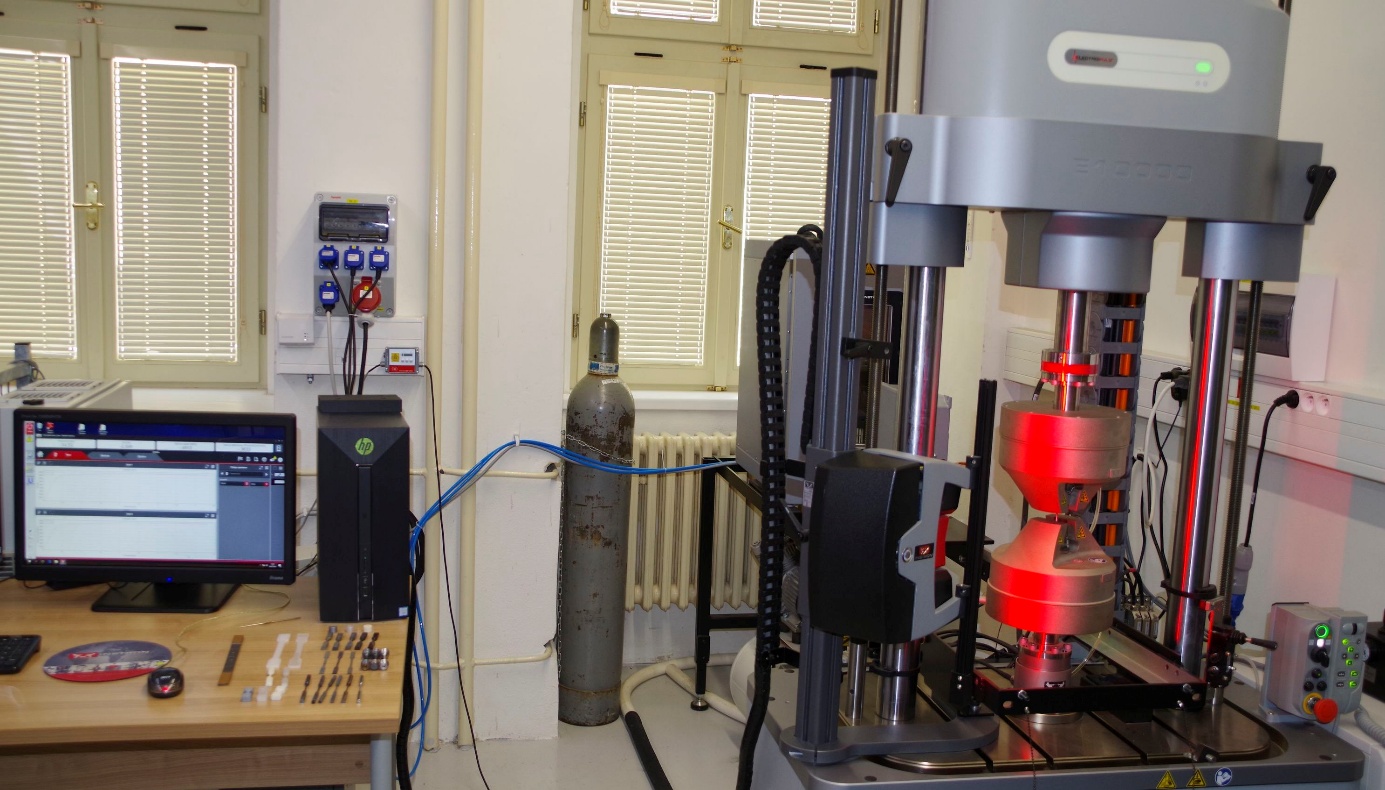

Equipment for mechanical testing

Evaluation of mechanical properties and behavior bulk materials

- Static loading - tension, compression, bending and torsion

- Cyclic overloading

- Low-cycle and high-cycle fatigue loading - tension, pressure, torsion and bending

Application in connection with technology processes and degradation processes

- Effect of surface treatments (PVD- ARC, magnetron, chemical heat treatment)

- Influence of degradation processes – temperature, corrosion and chemical

- Effects of ageing of polymers and composites - temperature, humidity and radiation

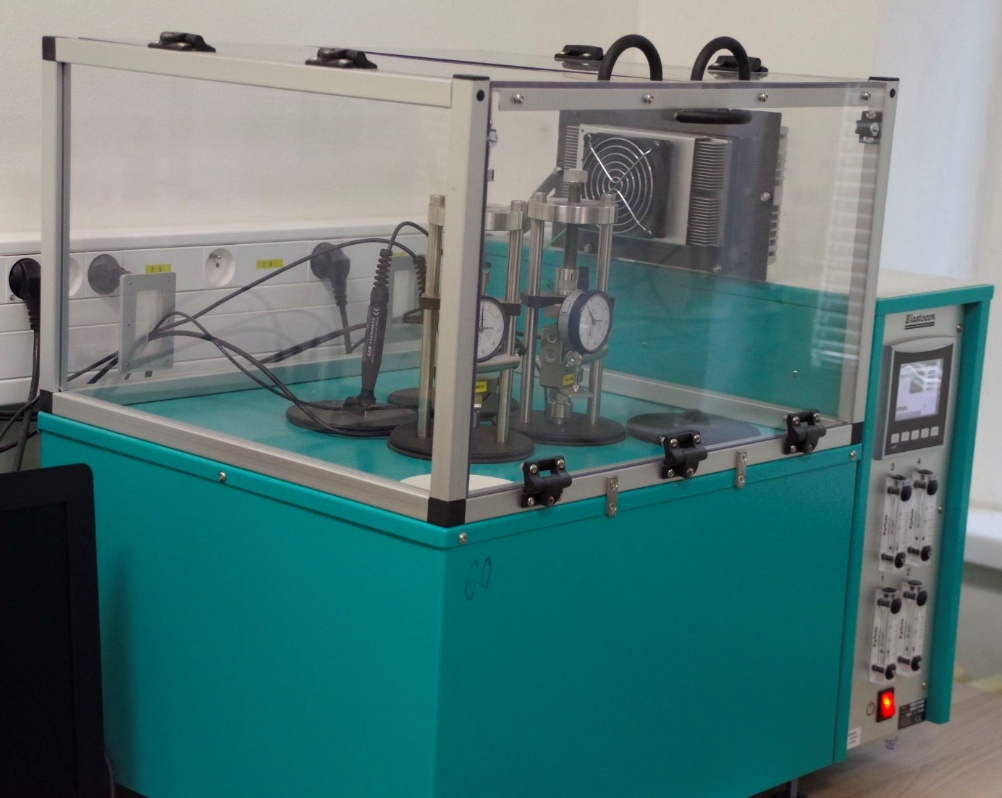

Equipment for evaluation of ageing of polymer and composite materials

Equipment for temperature ageing with relaxation in pressure

- Thermal ageing of polymers

- Evaluation of relaxation in pressure

Application direction

- Evaluation of materials for automotive, marine and railway

- Evaluation of materials in the field of cable insulation

- Evaluation of sealing elements

- Evaluation of materials for bio applications

Equipment for evaluation of humidity ageing

- Various chemical aggressions in the aqueous baths

- At room temperature

- At elevated temperatures

Equipment for evaluation radiation ageing by simulation sun radiations

Evaluation of the effects of radiation ageing simulation of sunlight by xenon lamps

Different combinations

- sun radiation

- the effect of defined humidity or showering

- the effect of heating temperature separates from sun radiation

Approximation of real conditions long-term exposure to the combined effects of polymer ageing

Monitoring the effect of sun radiation

- On selected polymeric materials

- On selected composite materials

- On surface treatment - Realized by technological surface treatment processes

Equipment for corrosion resistance testing

Simulation of corrosion action

Different combinations

- exposure to humidity

- the effect of the degree of humidity

- the action of salt fog

- water or saline shower tests

- effect of temperature

- Approximation of real conditions long-term exposure to the combined effects of corrosion

Testing in chambers with defined conditions

environment

- salt solutions

- solutions of acids

- electrochemical environment

temperature

- at room temperature

- at elevated temperature

directions of evaluation

- Corrosion initiation

- Corrosion development

- Analysis of corrosion protection possibilities

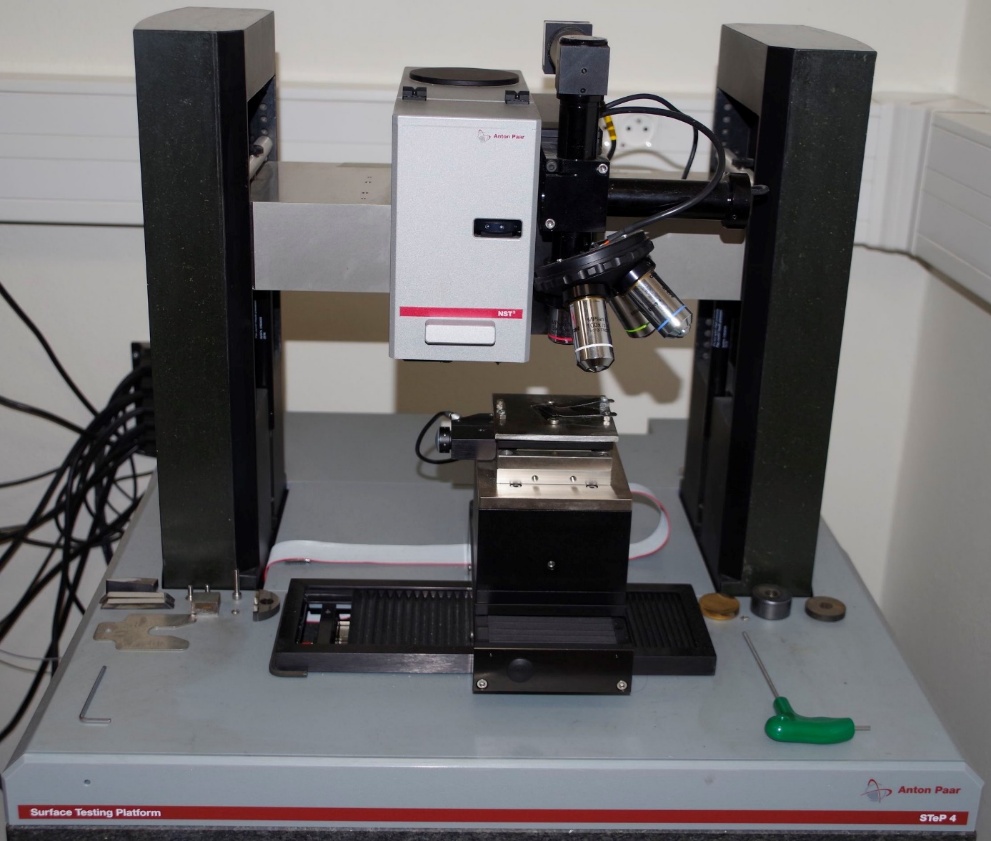

Equipment for evaluation of mechanical properties and behaviour of surface layers and systems of surface layer - basic material

Indentation measurements over a wide range of normal loads

Devices

- nanoscratch tester

- macroscratch tester

- hardness tester Ernst

- indentation measurements Epuls

Methods of measurements

- Static measurements in different modes

- Scratch measurements in different modes

Application

- evaluation of hardness characteristics

- evaluation of elastic-plastic behavior

- evaluation of brittle fracture properties

- evaluation of adhesive-cohesive behavior of systems thin films - basic material

- evaluation of local fatigue properties

- evaluation of friction properties and wear

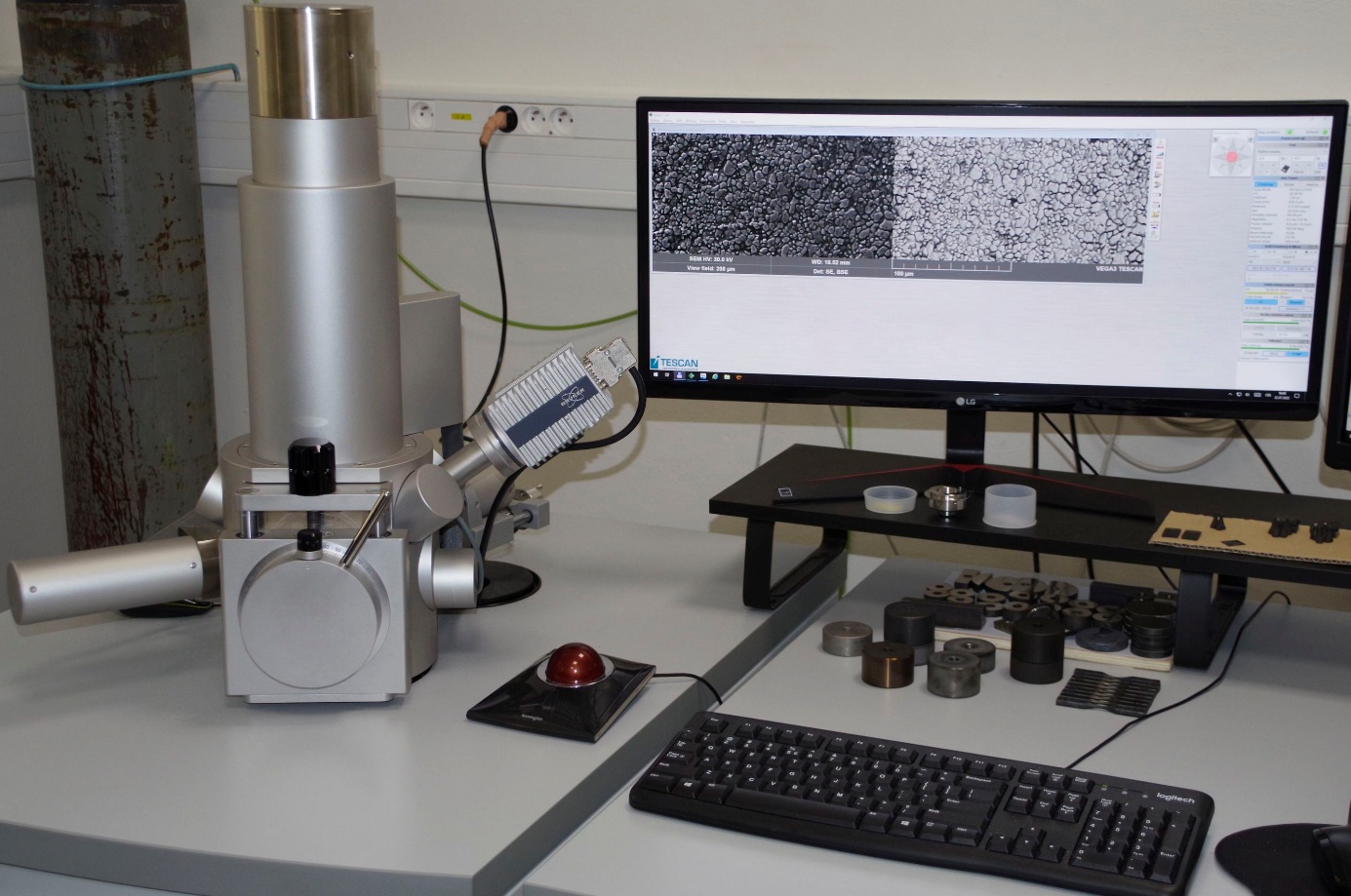

Equipment for evaluation of surfaces morphology and fractures, structure, phase and chemical composition

Complex focus on evaluation of results from all of the above mentioned equipment’s

- Evaluation of morphology, structure and phase and chemical composition

evaluation of basic bulk materials

- Evaluation of materials after various heat treatments

- Evaluation after various chemical heat treatment processes of surfaces

- Evaluation after different technological processes of HC490 deposition

- Evaluation after long-term thermal loading

- Evaluation after various corrosion tests

- Evaluation after different ageing processes

- Evaluation of failures and fractures after mechanical load tests

- Static

- Quasi-static

- fatigue

- Evaluation after all types of indentation tests

More information about the Laboratory of Surface Technologies and Degradation of Materials in Pilsen can be found here information booklet