Like Jekyll and Hyde – that’s how some materials behave. An international team led by Hanuš Seiner from the Institute of Thermomechanics of the CAS has found that in some directions an alloy of nickel, manganese and gallium is able to transmit elastic waves faster than steel, but in other directions the pulses propagate more slowly than in air. To describe the alloy’s behaviour, scientists had to decipher it, atom by atom. The study was published in the prestigious journal Advanced Materials.

Take the hammer and strike the anvil with all your might. The hammer will bounce off the anvil, but the anvil will appear to remain motionless. But the force that makes the hammer bounce is generated in the hard material of the anvil in response to the blow. It is made possible by the elasticity that is specific to each material. And it is this elasticity that scientists at the Institute of Thermomechanics of the CAS and the Institute of Physics of the CAS are studying.

“It tells us the forces that hold the atoms in the lattice together. You need to know this if you want to work with the material further,” explains Kristýna Repček from the Department of Ultrasonic Methods at the Institute of Thermomechanics of the CAS. Graphite is a well-known example of anisotropy – it is very soft in one direction, so that simply brushing it against paper breaks the bonds of the carbon atoms in its lattice, leaving a mark. In the perpendicular direction, however, it is very hard due to its strong bonds. The nickel-manganese-gallium alloy (Ni-Mn-Ga), which has been of interest to the scientific community for over twenty years, has a similar property.

Multiscale structure of Ni-Mn-Ga crystals: from a macroscopic crystal with visible deformation bands to a layered atomic lattice.

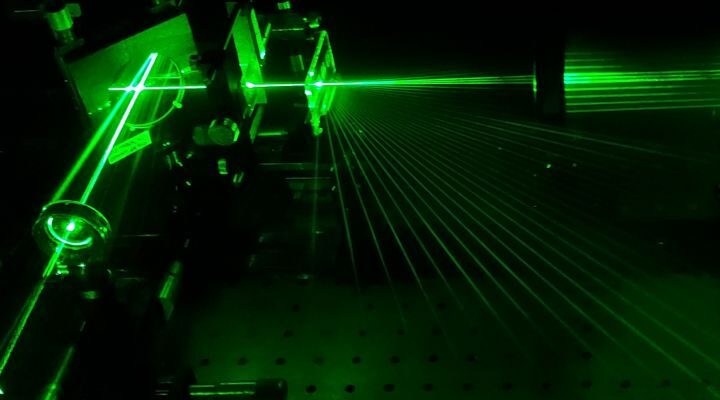

But it is only now that Czech physicists, in collaboration with the Lappeenranta University of Technology in Finland, have managed to decipher the elasticity conditions of Ni-Mn-Ga in detail. To do this, they had to perfect a method of transient grating spectroscopy, which allows the mechanical response of crystals to laser pulses shorter than a nanosecond to be recorded. There are fewer than ten laboratories in the world that can work with this technology, and only the Institute of Thermomechanics of the CAS has developed an ultra-transient grating version of it, capable of analysing material responses many times shorter. “Thanks to it, we are able to obtain the most information on the elasticity of materials in the world. We can find out its elasticity without touching it. And even for layers that are only a few micrometres thick, it’s really unique. I think the development of the method itself is an important contribution of our work,” says Kristýna Repček.

Magnetically controlled motion

The anisotropy of elasticity in Ni-Mn-Ga is so extreme because an unusual deformation mechanism takes place in the alloy at the atomic level. The same mechanism also allows the development of supermobility, i.e. high strain mobility in the crystal lattice. Thanks to this, even a very weak mechanical force or a small change in the magnetic field can cause a visible change in the shape of a Ni-Mn-Ga crystal.

Ni-Mn-Ga belongs to the family of shape memory alloys, i.e. metallic materials whose shape can be changed in a controlled manner by changing external conditions. Its “relative”, the nickel-titanium alloy or nitinol, is now routinely used in a number of industries, such as orthodontics. It can also be found in spectacle frames, hydraulic systems in fighter jets or bra reinforcements. In the case of nitinol, however, the change in shape is achieved by changes in temperature.

The fact that the same effect can be achieved with Ni-Mn-Ga using magnetism is a huge advantage, as Kristýna Repček points out. Ordinary nitinol would have to be heated and cooled over and over again, which takes time – you have to add and remove energy. Whereas if you could just move a magnet over the material, you’d get orders of magnitude faster speeds. Other advantages of the Ni-Mn-Ga alloy include its stability or resistance to vibration.

Deformation of a Ni-Mn-Ga-Co-Cu alloy crystal by an external magnetic field. The photographs show the same crystal taking on different shapes in a magnetic field lying in the plane of the image (left) and perpendicular to the plane of the image (right).

Subcutaneous drug delivery

It can be used in a variety of sensors, where the material responds to a change in conditions and provides information about it, or in actuators, where a human provides the impulse and the material makes the change. A very concrete application could one day be a micropump for drug delivery directly under the skin. The chip measures blood glucose levels and, if it detects an overshoot, instructs the micropump to draw a drop of medication from a reservoir and deliver it to the site where it is needed. The development of micropumps with supermobility in Ni-Mn-Ga is being pursued at several sites around the world. “I have seen a working prototype of such a device even as a high school project, so I believe that such an application is not unrealistic,” says the scientist.

However, nickel-manganese-gallium still has a long way to go. The measured constants will be used by other experts to create a model of the material and make suggestions on how to improve the alloy. It is already known that in its current form it does not have very suitable thermal properties for applications.

The direct observation of the mechanical instability of Ni-Mn-Ga alloy crystals is the first groundbreaking result of the half-billion-CZK OP JAK FerrMion project, and the team of scientists led by Hanuš Seiner from the Institute of Thermomechanics of the CAS will now focus on other phases of the alloy or the aforementioned thermal properties.

Magnetic shape memory

It is well known that magnetic fields can be used to move some metal objects at a distance. But can you also change their shape? Magnetic alloys with shape memory can. It looks like a magic trick: without touching the Ni-Mn-Ga-based alloy crystal, we simply change the direction of the external magnetic field and the metal crystal deforms to the point where it is visible to the naked eye. Why does this happen? The crystal lattice tries to arrange itself so that its own magnetic moments are parallel to the external field. In conventional materials, this can only be achieved by rotating the whole object. In an alloy with supermobility, however, it is easier to deform according to the magnetic moments. This phenomenon was first described at the turn of the millennium by groups from the Helsinki University of Technology in Finland and the Massachusetts Institute of Technology in the USA.

Text: Jana Bečvářová, External Relations Division, Centre of Administration and Operations of the CAS

Photo: Marek Vronka, Institute of Physics of the CAS; Lucie Bodnárová, Institute of Thermomechanics of the CAS; David Mareš, Institute of Thermomechanics of the CAS (header image – spectroscopy apparatus with transient grating)

The original article was published in Czech on the website of the Czech Academy of Sciences.

The text is released under a Creative Commons licence.

The text is released under a Creative Commons licence.